Heading into the future

2010–2024

Despite the effects of the last global economic crisis in 2008/2009, Elektror is proving resilient and demand for Elektror products continues to rise. Elektror is responding to this encouraging development by expanding production capacity at the Waghäusel-Kirrlach site in 2013.

A year earlier, in 2012, the production area for large-volume steel fans quadrupled with the relocation of Polish production from Zabrze to the new plant in Chorzów.

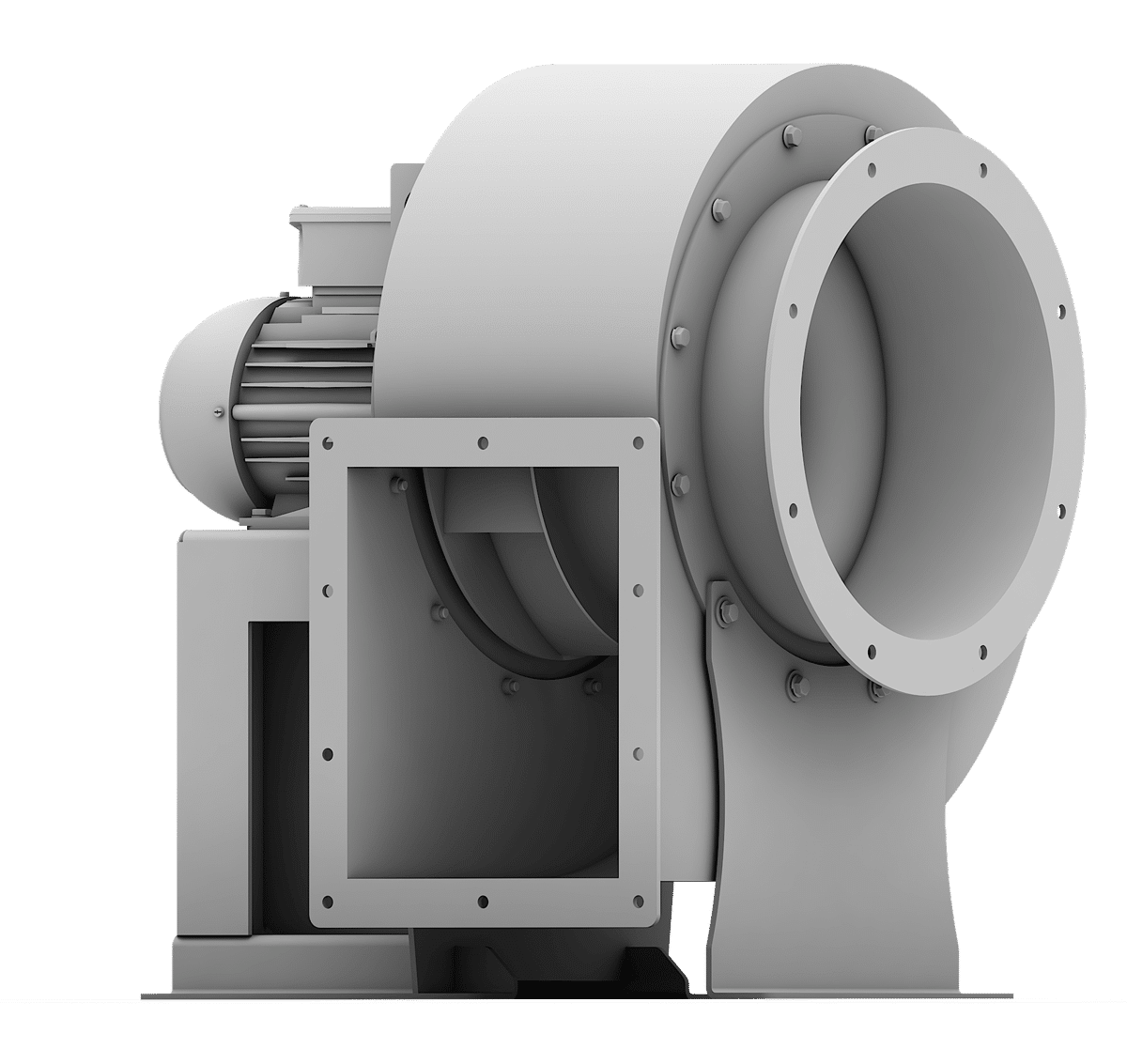

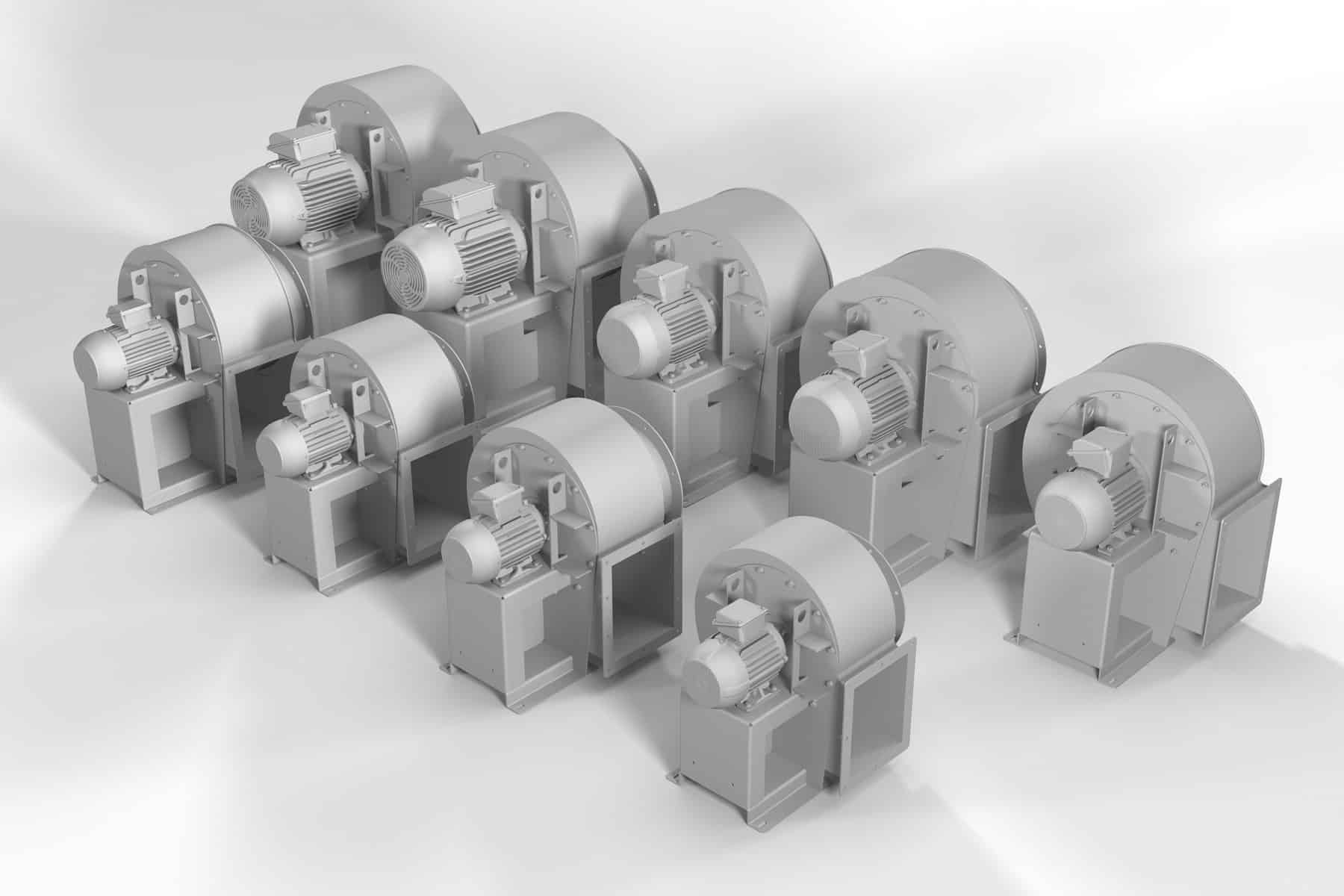

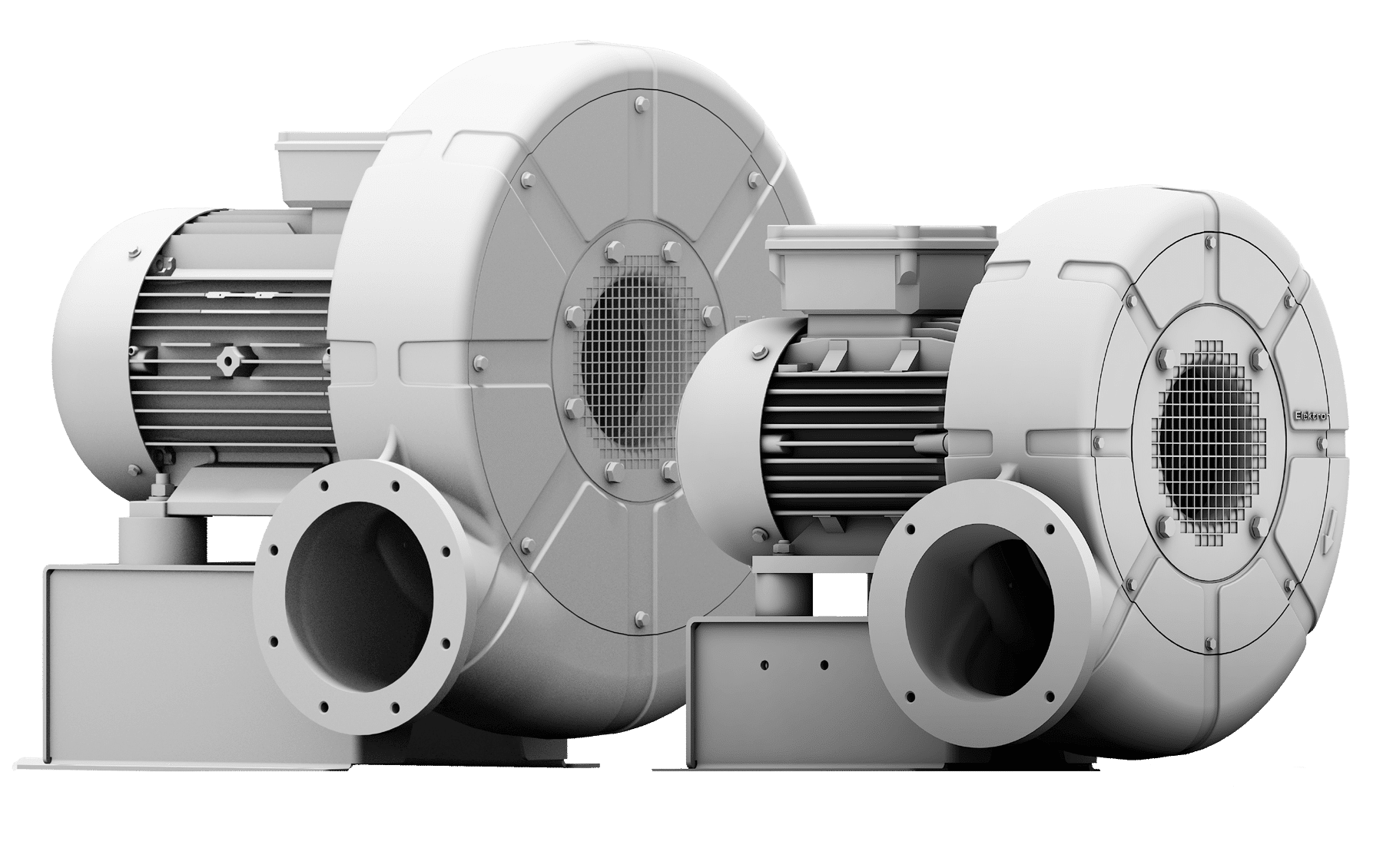

In response to numerous customer requests, Elektror began developing its cast aluminum low-, medium- and high-pressure series in stainless steel back in 2011.

The laser-welded stainless steel series S-LP, S-MP and S-HP are now available in their entire variation for a wide range of applications.

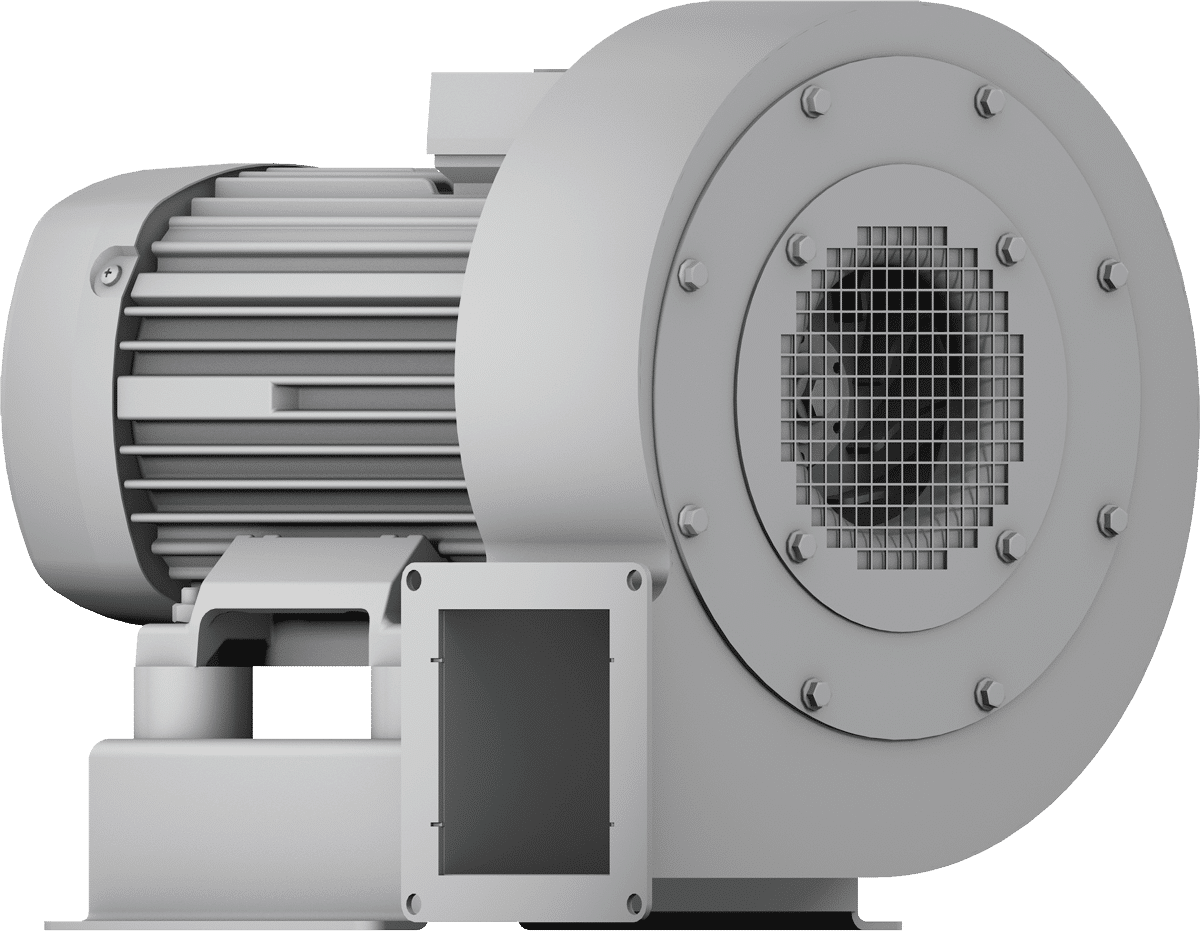

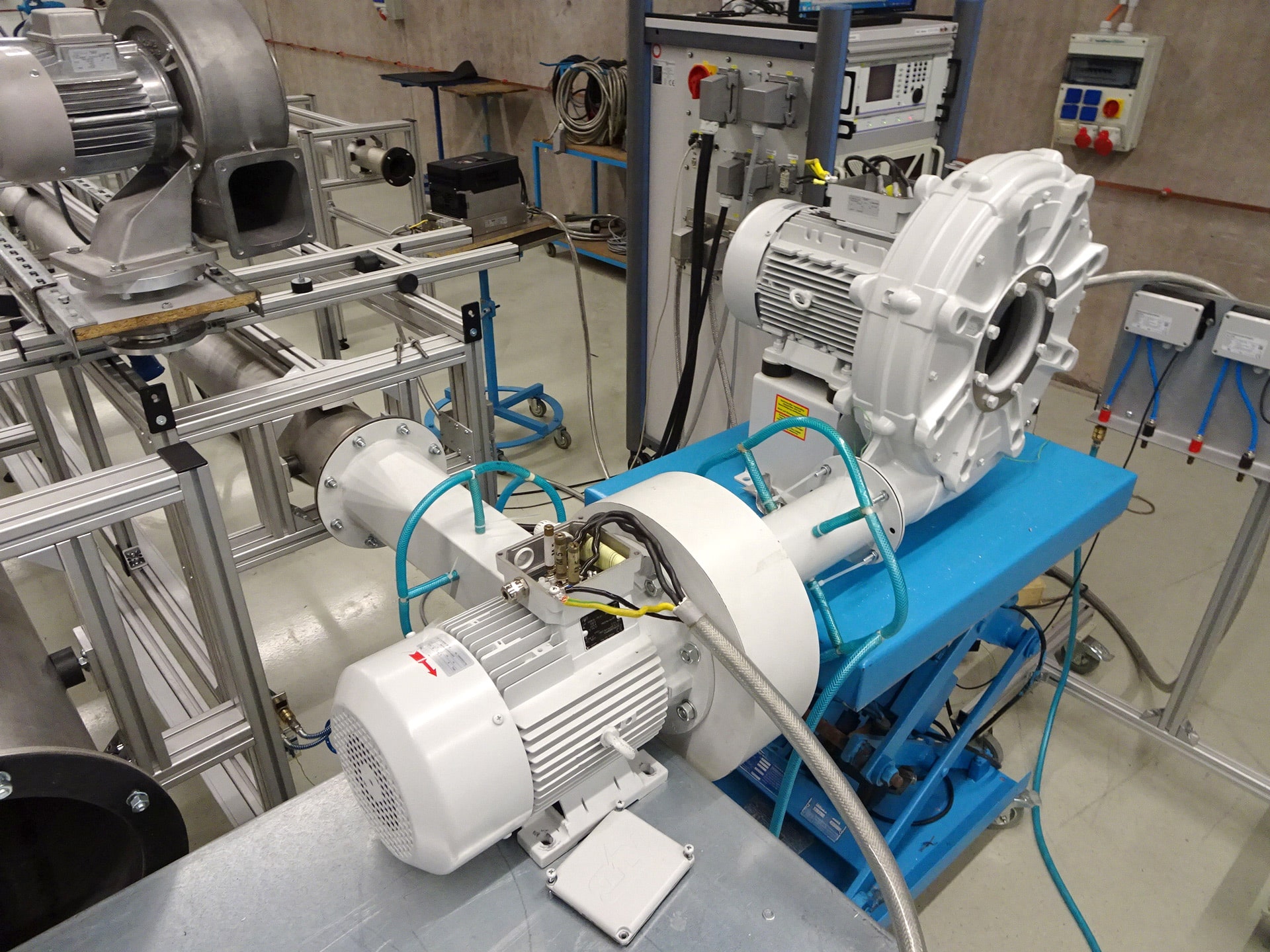

Driven by the desire for even more compact and powerful devices, Elektror developed a new benchmark for high-performance fans for a global market leader in the food and beverage industry in 2013. The resulting S-XP (Steel Extreme Pressure) series, with its performance data of up to 250 Hz (15,000 rpm), represents the state of the art in high-performance fan construction.

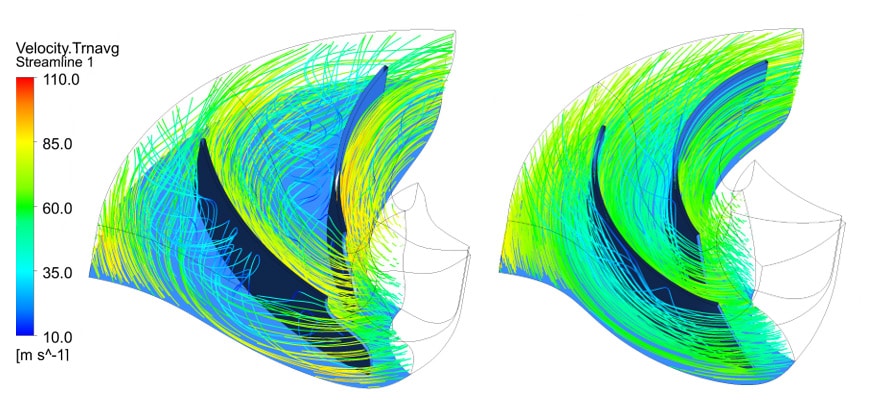

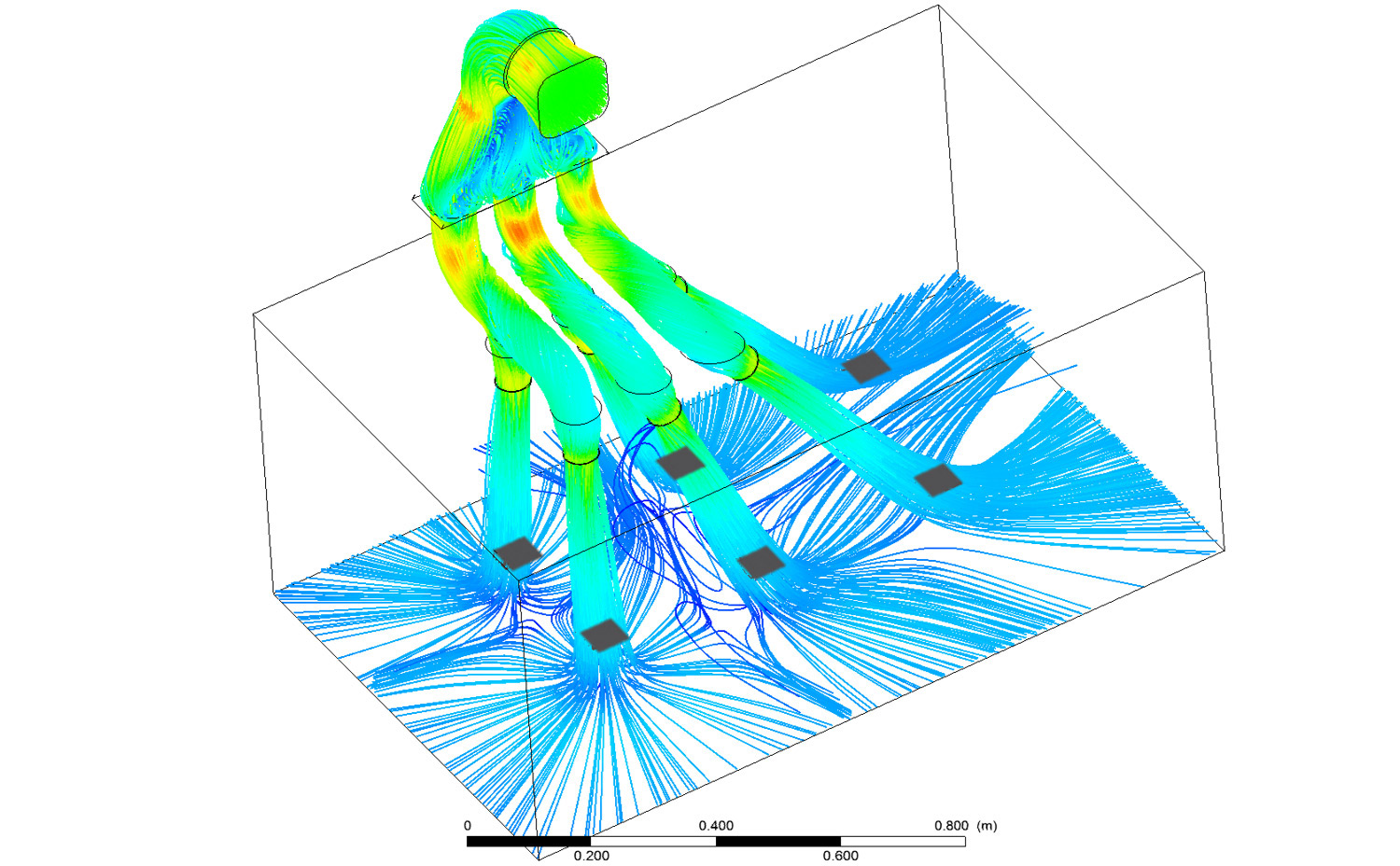

Elektror recognized early on the need to systematically promote the topics of strength, acoustics, bearing design, rotor dynamics and CFD, i.e. air technology design expertise, as one of its core competencies. To this end, Elektror set up a new pre-development and research department, which from then on dealt with overarching topics relating to flow, strength and vibration design and optimization at maximum speeds, independently of day-to-day business. Always following the principle that even the most sophisticated fan technology must meet the highest requirements for durability and efficiency in continuous industrial use.

Supported by the Margarete Müller-Bull Foundation, which made a doctoral position possible, the new “Technology Development and Simulation” department was launched in 2015 and remains Elektror’s think tank to this day.

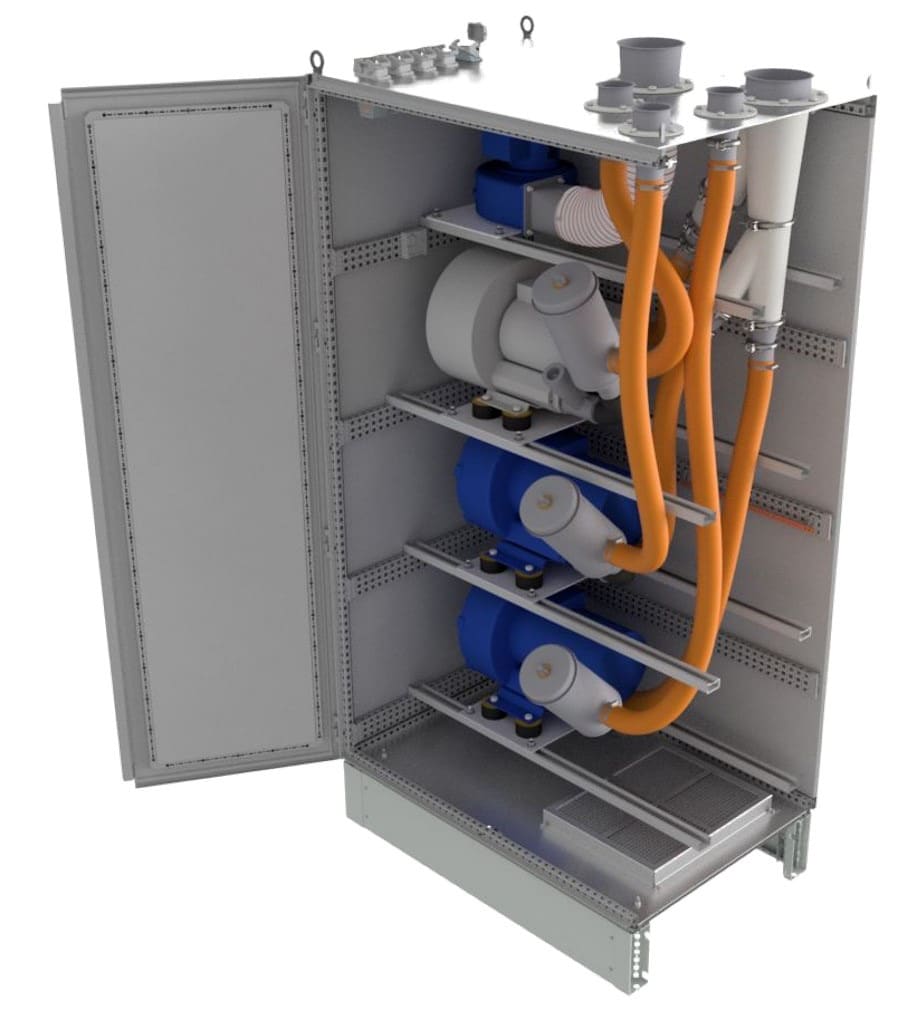

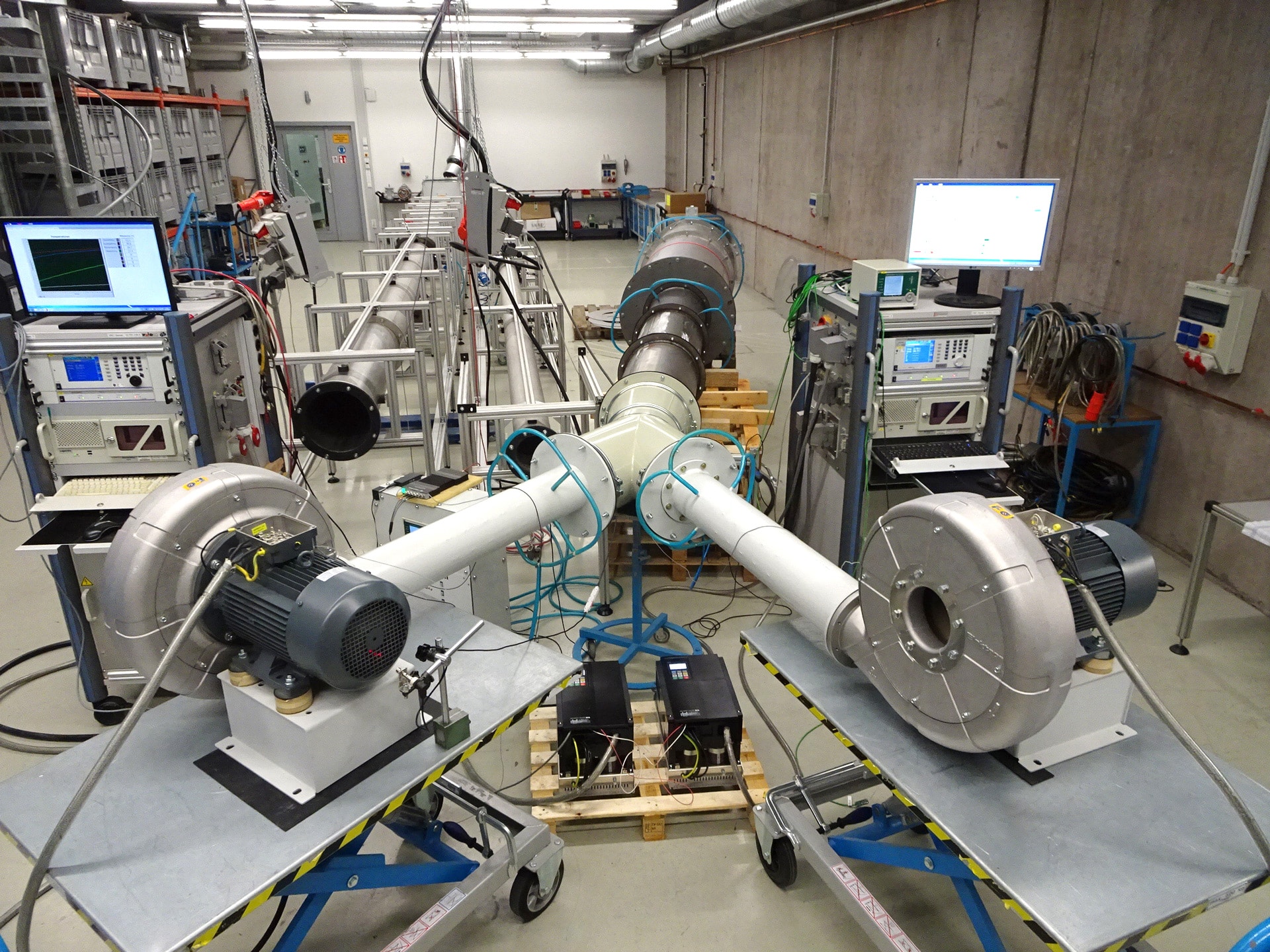

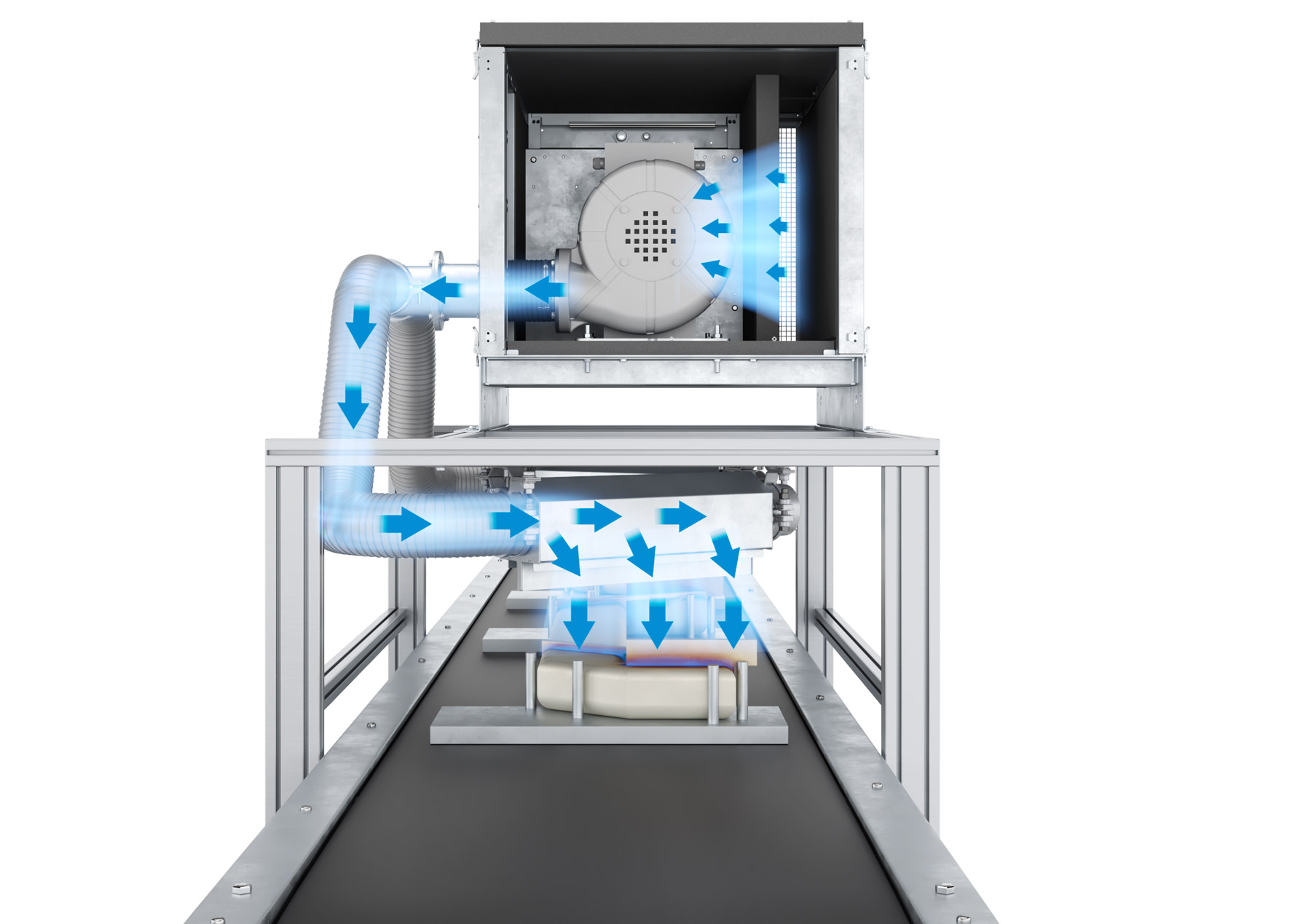

2015 marks another milestone in Elektror’s customer focus. With the establishment of the Systems & Solutions division, Elektror is responding to the ever-increasing customer demand to be able to integrate plug & play-capable air ducting systems into their systems instead of individual components. The basis for this is, on the one hand, almost 100 years of application expertise and, on the other, the systematic expansion of the product range to become a system provider.

In 2015, another doctoral thesis supported by the foundation will also be carried out at Elektror. It deals with the parallel and series connection of high-performance fans. Mastering this technology opens up new characteristics in both the volume and pressure ranges.

Swing-out fans will be introduced in 2016. These are characterized by the fact that the impeller can be extended from the housing both mechanically and hydraulically. These fans, which are usually made of stainless steel, are specially designed for the cleaning-intensive food industry.

In 2019, the experience gained over the past decades culminated in the new S-HE (Steel High Efficiency) fan series. This laser-welded steel series features the latest impeller technology in terms of high efficiency and energy consumption optimization and thus meets the increased customer requirements in terms of sustainability.

Elektror opened another important chapter on its path to digitalization and modernization in 2019. By converting the Elektror Group’s system landscape to SAP and the associated SAP Business Intelligence, the company was prepared for the next steps towards digitalization.

In the same year, Elektror launched an internal training and further education program with the Denkfabrik. It includes live seminars, workshops and online courses for employee onboarding and training.

The Elektror Group also took over Promet GmbH from Plüderhausen near Stuttgart in 2019. With the additional expertise in sheet metal processing, Elektror completed its range of services from components to complete systems. Always following the maxim of making complex ventilation systems as simple and efficient as possible for the customer.

The knowledge gained from research and pre-development has resulted in the A-HP (Aluminum High Pressure) series, developed according to the latest aerodynamic and design findings. This series is characterized by maximum efficiency and vibration optimization and delivers an enormous power density with the most compact design.

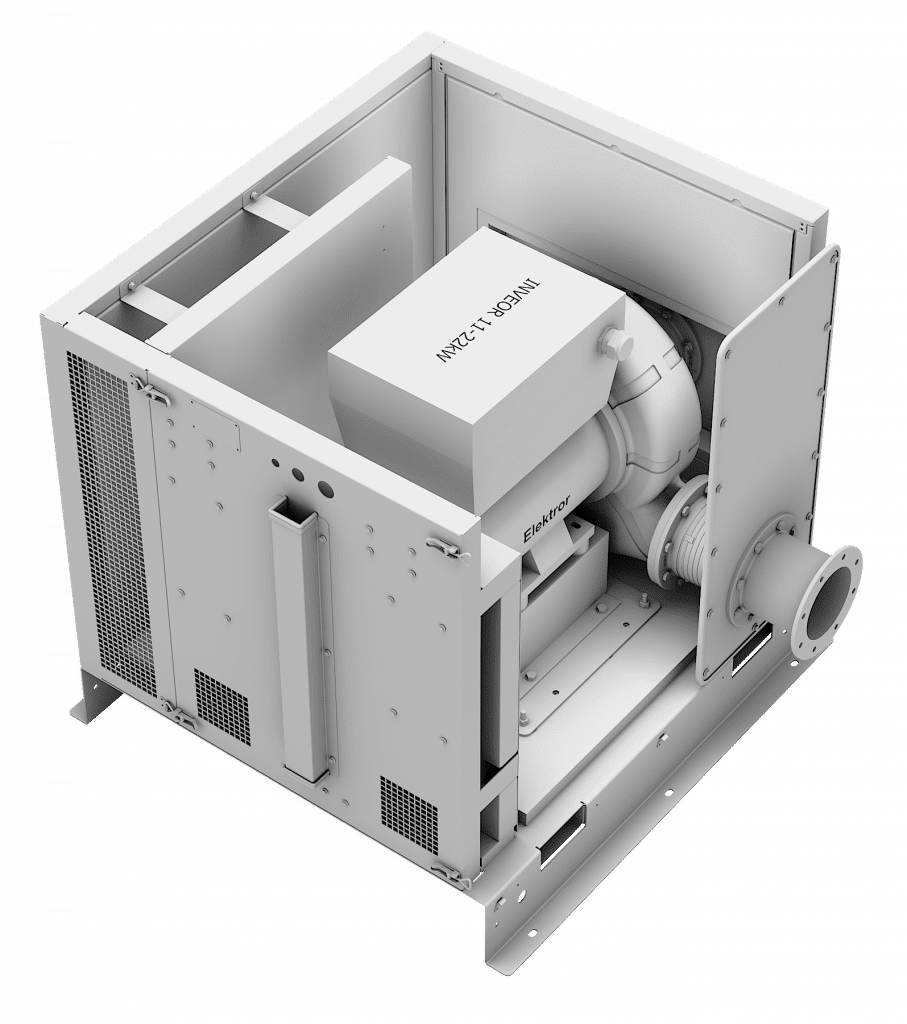

Elektror is developing The Box sound insulation system in 2021 to meet the legal and technical requirements for the physically high noise levels of high-performance fans. This decentralized system enables the operation and control of all high-performance fans and can be expanded to include air filtration.

Elektror has been represented in China by its own sales company in Beijing since 2008. In addition, the sales office in Changzhou was opened in 2019 and the sales office in Chengdu in 2021 in order to meet the constantly increasing market demand. In 2023, Elektror takes an important strategic step to drive forward its internationalization strategy – a production plant is opened in Changzhou (Greater Shanghai Area). This not only provides Elektror with even better market access, but also enables its European customers to operate even more competitively in Asia with immediate effect.

The year 2024 will be marked by Elektror’s 100th anniversary. Customer events and events for employees accompany the festivities around tradition, inventiveness, innovation and progress.

At the same time, the conversion to the current SAP S4/Hana is taking place so that Elektror is also ideally positioned for the transformation into the future on the system side.

100 years of Elektror

100 years of ventilation technology through quality and inventiveness

Karl W. Müller laid the foundation stone with his vision and firm conviction that air as a working medium, so-called process air, would make a decisive contribution to the industrialization of a wide range of industries and areas of application. He was right, and today Elektror supplies a wide variety of customers in mechanical and plant engineering. Wherever air is used as a working medium, Elektror offers the right solution. Elektror has made it its mission not only to provide its customers with the best possible advice and support, but also to invest all its energy in the continuous development and optimization of its products, systems and services with regard to the use of resources, energy efficiency and sustainability.

Elektror looks to the future with great confidence and gratitude – far beyond the next 100 years. Based on the inventive spirit of Karl W. Müller, the steadfastness of Margarete Müller-Bull and the entrepreneurial foresight of Ulrich W. Kreher, we can look back on a century of success together with our valued customers and employees. You can continue to rely on us in the future.