Millennium change and advancing digitalization

2000-2010

In 2001, Mrs. Margarete Müller-Bull appoints Mr. Ulrich W. Kreher as her successor and appoints him as managing director with sole power of representation. Thanks to the many years of trustful cooperation between Ms. Müller and Mr. Kreher, she knows that Elektror is in good hands.

On Sunday morning, March 17, 2002, Mrs. Müller-Bull passed away after a long, eventful and fulfilling life. In accordance with her last wishes, the company was transferred to the Margarete Müller-Bull Foundation with the support of her long-time confidant and tax advisor, Mr. Franz Longin. Its purpose was and is not only to maintain and further develop the company, but also to support humanitarian causes, animal welfare and the promotion of science and technology, which were close to the founder’s heart throughout her life.

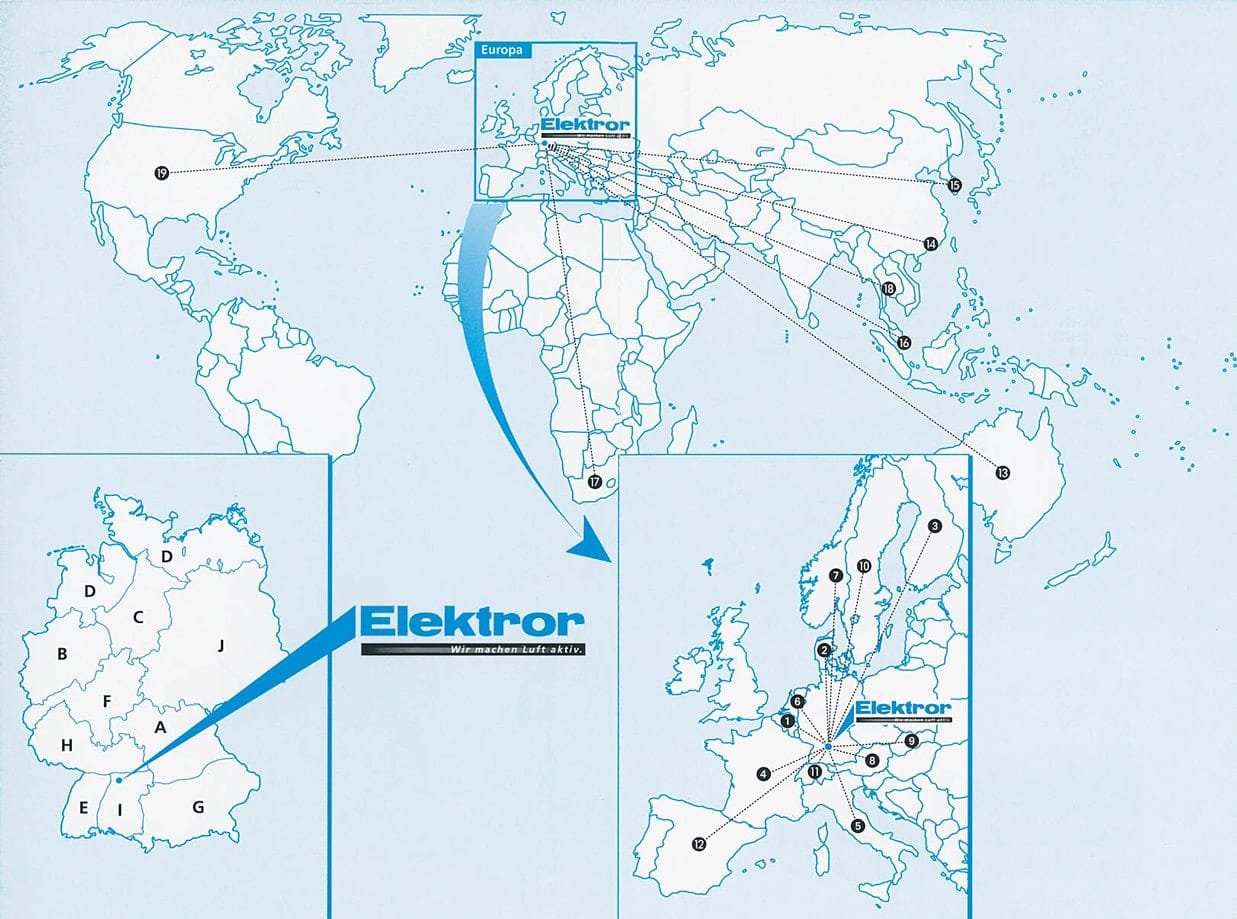

Focused on the core competencies, Mr. Kreher makes important decisions for the continuous development of the Elektor Group in the first years of the new millennium. All aluminium foundries will be sold by 2004 and the focus will be placed on internationalization and the development of the product portfolio. As a result, not only have existing sales representatives become Elektror employees, but the number of Elektror representatives abroad has also been greatly increased, true to the motto: “Think global, act local”.

On June 18, 2006, Elektror Karl W. Müller GmbH Co. KG was renamed Elektror airsystems gmbH. The new name reflects the company’s strategic focus on complete ventilation systems. At the same time, the company expanded its product portfolio to include frequency inverters that enable precise speed control of the motors.

Elektror is also making further efforts to expand its international presence. For example, a production site for large-volume steel fans was opened in Poland (Zabrze) in 2007.

Elektror thus significantly expanded its product portfolio and further strengthened its position as a single-source supplier in ventilation technology. The performance spectrum now ranged from small low-pressure fans with a drive power of 125 watts to true fan giants with a drive power of up to 1,000 kW and an impeller diameter of up to four meters.

At the same time, Elektror’s global representation was expanded with the opening of the sales company in Austria and the first non-European representative office in China in 2008.

Elektror’s steady growth was also reflected in the increasingly cramped conditions at the Esslingen site. For years, attempts have been made to cover the additional space requirements by expanding the existing areas. Unfortunately, the purchase of neighboring apartments and properties did not bring any real improvement, as the employees spent their working day scattered far and wide. Short distances and coordination options were no longer available.

For this reason, it was decided back in 2004 to look for a suitable location for Elektror. Supported by a master’s thesis on the topic of “Elektror’s new location search”, the decision was made to build the new Elektror Group headquarters at Scharnhauser Park in Ostfildern. This location offered optimal transport connections by bus, train and car as well as short distances to the airport.

The modern and light-flooded Elektror headquarters not only stands for a contemporary working environment, but also underlines Elektror’s conviction that the working environment and equipment contribute to positive cooperation and promote creativity and inventiveness.

In the same year, 2008, Elektror introduced an environmental management system in accordance with DIN EN ISO 14001, which illustrates the company’s continuous efforts towards sustainability and resource conservation.

In 2009, the Elektror sales network was expanded to include a branch in the Netherlands.

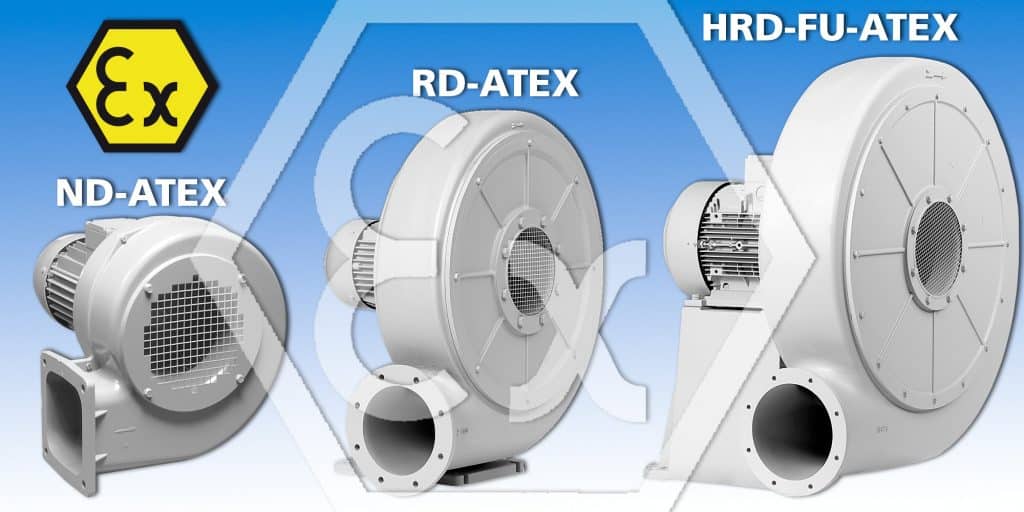

Also in 2008, an ATEX version (explosion-proof version) with a speed-controlled and pressure-encapsulated motor was added to the high-pressure series. From now on, Elektror will also be offering all series from low-pressure to high-pressure fans in ATEX versions.

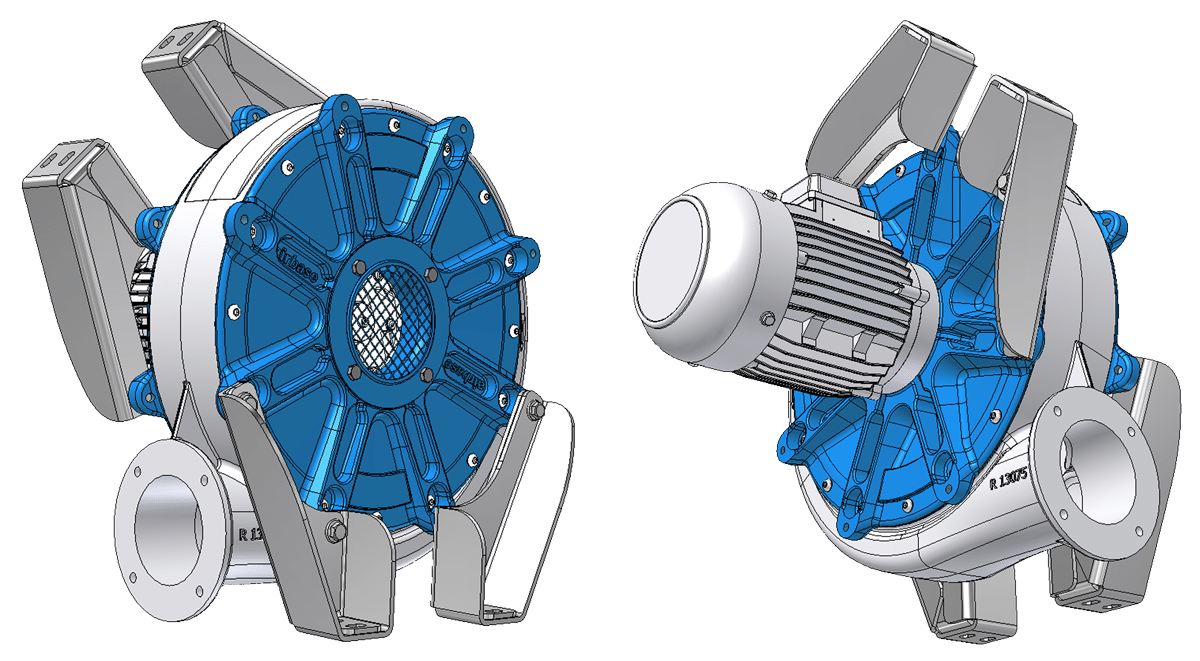

Driven by the increasing demand for compact high-performance fans from well-known mechanical engineering customers, Elektror continuously pushed development in the high-pressure range and ushered in a new era with the HRD Boosted series in 2010. Since then, standard high-pressure fans with up to 135 Hz (8,100 rpm) have been the measure of all things. This has pushed the boundaries of what is possible.

The portfolio was supplemented by the “airbase” mounting system, which considerably simplified the vibration-optimized installation of high-performance fans in mechanical engineering.