Pioneering spirit in times of crisis

1920s–1940s

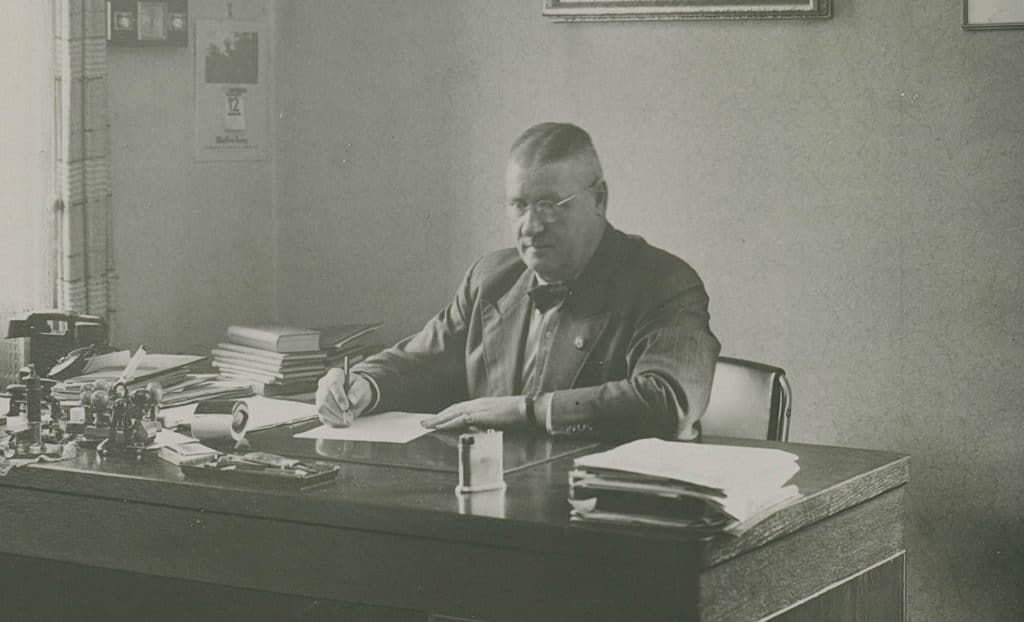

Driven by his inventive spirit and his great passion for engines – in economically extreme times – Karl W. Müller plucked up the courage to give up his secure job as a trainee lawyer at the age of 34. With nothing but a typewriter, he ventured into self-employment to realize his lifelong dream. He was convinced that he could make a real contribution to technical progress with his ideas and inventions in the prevailing shortage economy: Motors for the world!

This was followed by the registration of Elektror-Motoren-Handelsgesellschaft in Esslingen am Neckar on October 15, 1924. Business is tough and the available funds are dwindling under the dramatic devaluation of money.

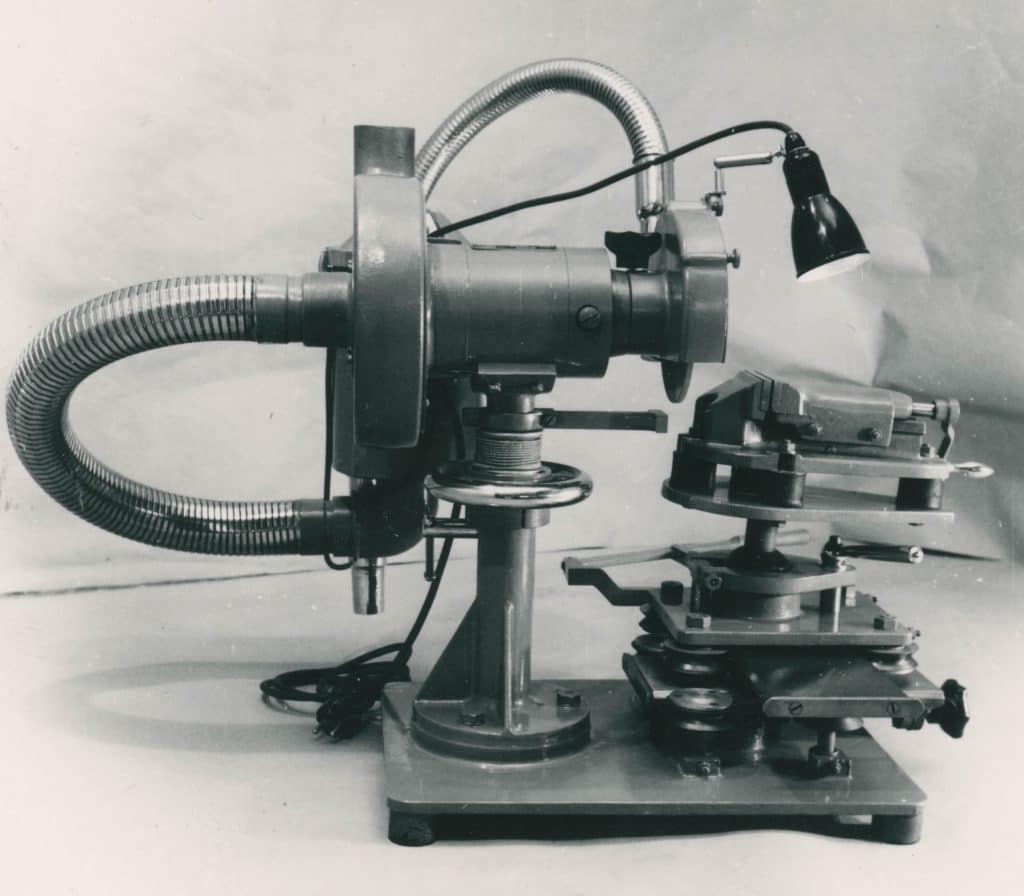

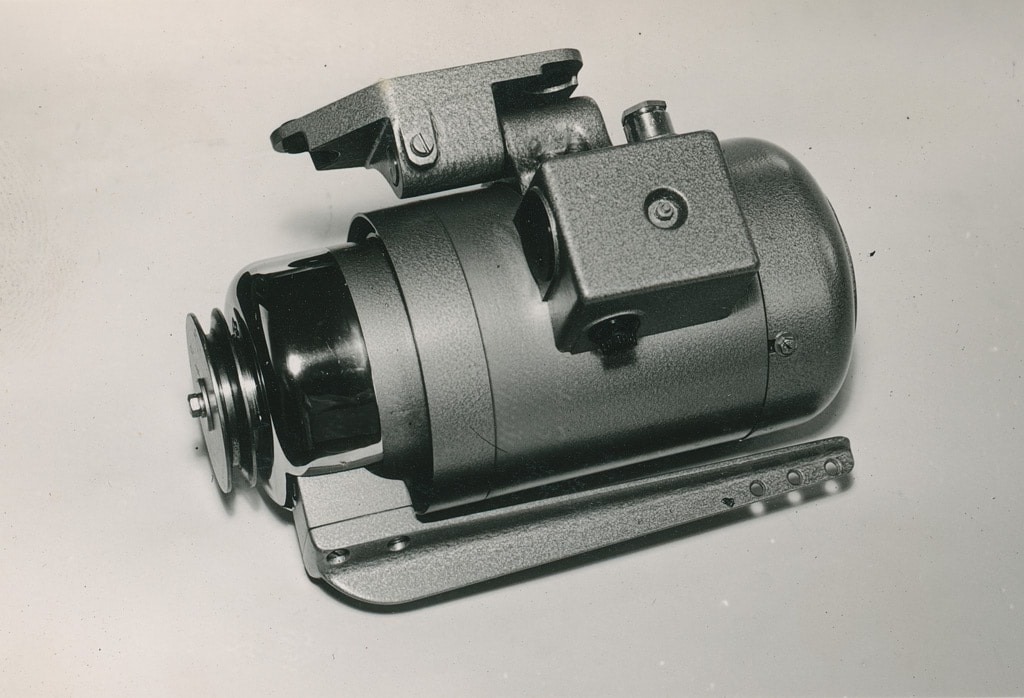

Despite inflation and the looming global economic crisis, Karl W. Müller ventured into in-house engine production in 1925. In the early days, he concentrated on a wide variety of motors, which he developed himself with his small team. In the 1920s and 1930s, a wide variety of special motors were initially developed. These include, for example, sewing machine motors, vibration motors and motors for shoe production. He was always on the lookout for interesting applications for his motors. In doing so, he concentrated on promising niches.

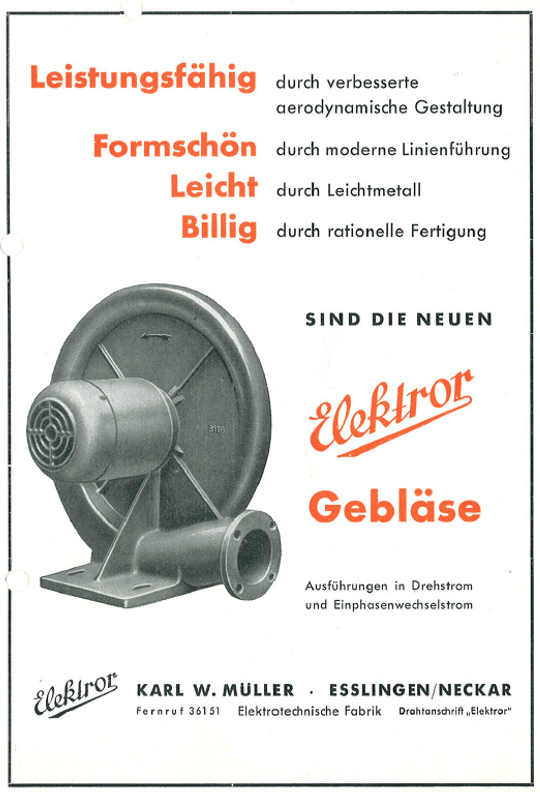

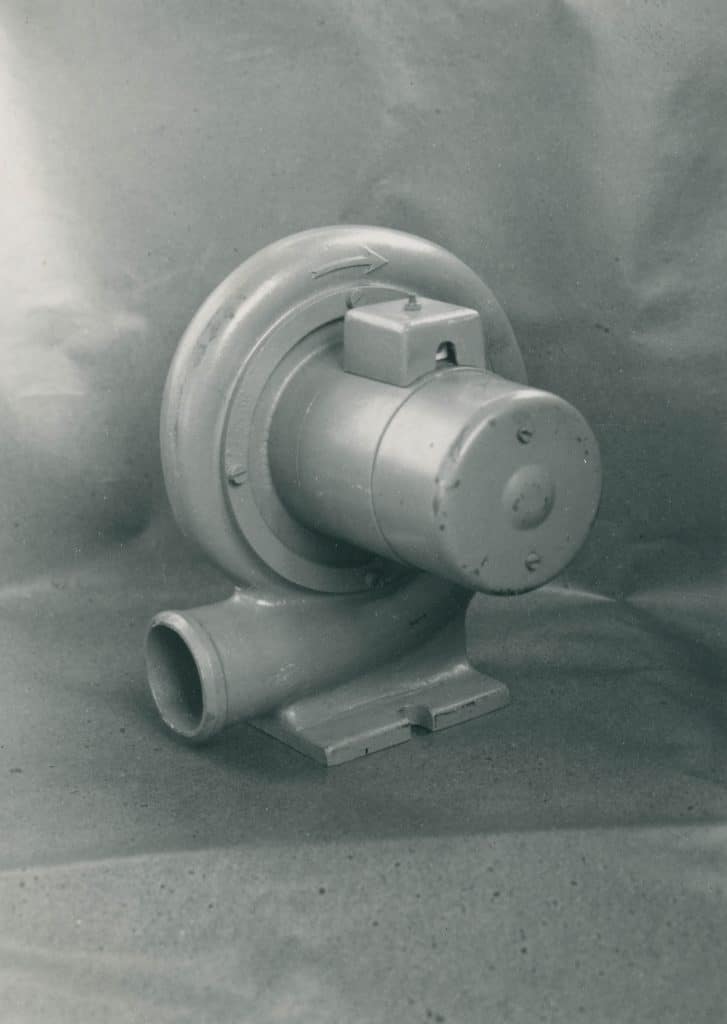

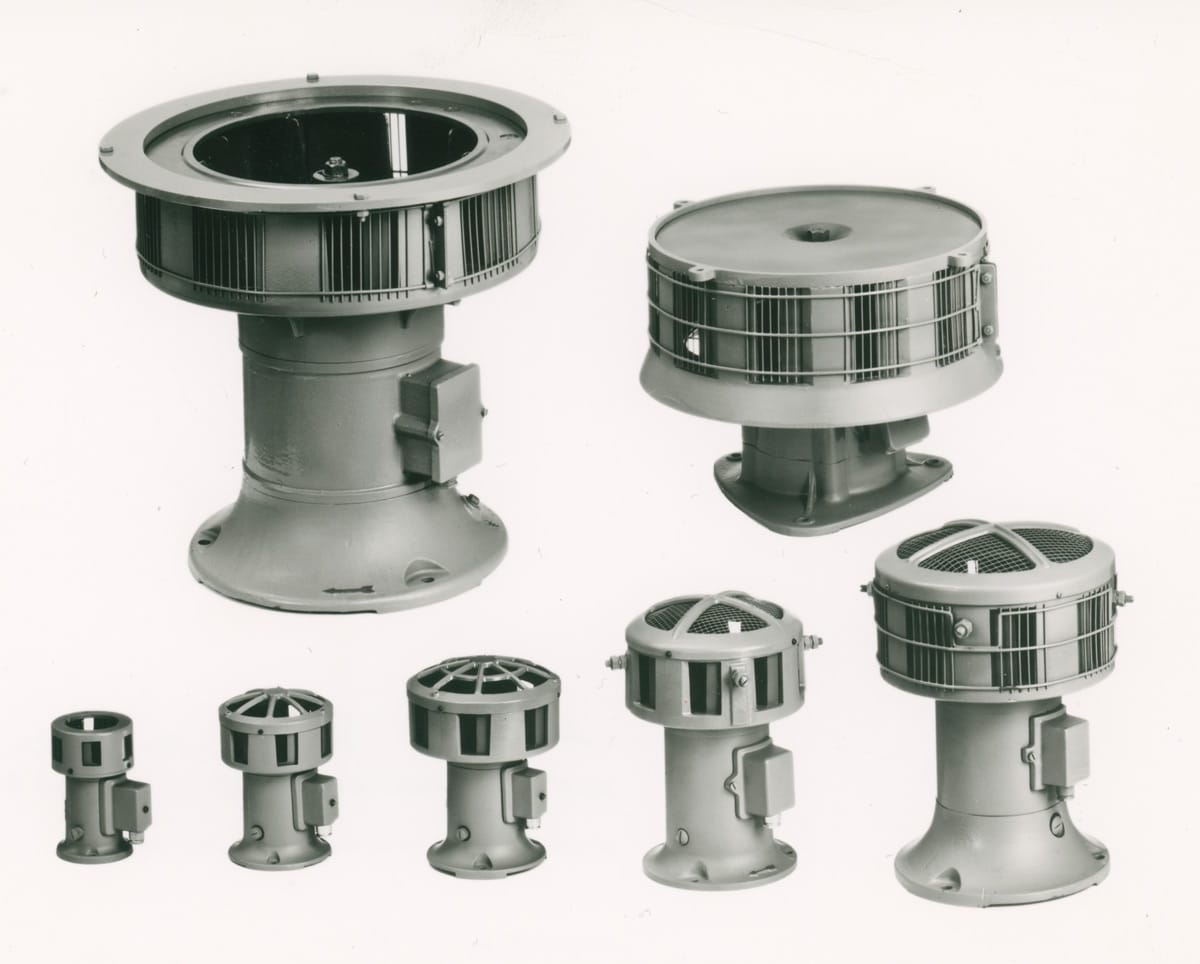

By 1935, Elektror had long since established itself and was ready to move to larger premises in Esslingen. A clear sign of growth and ambition. In addition to individual electric drives, the focus was now on the first extraction and fan blowers. With entrepreneurial flair, he decided early on to create the conditions for the certification of standardized sirens by the Office for Civil Protection. The first series was created, which laid the foundation for the company’s further focus on air technology. From then on, the focus was on electrically powered fan technology and the expansion of the product portfolio.

In 1942, part of the production is relocated to Waghäusel in Baden. A former cigar factory is being used there and adapted to production requirements. During the war years, there was a great need for Elektror air-raid sirens and bunker fans. Sirens are now manufactured in large quantities at the production sites in Esslingen and Waghäusel. Committed to the highest product quality, all products are extensively tested before delivery. Even with soundproof cabins, the “song” of the sirens could still be heard, earning Elektror the nickname “Siren Müller” among the population.

Interesting facts about the Waghäusel plant, Kirrlach district

At the beginning of August 1942, the Elektror-Motorenbau company came to Kirrlach and rented an empty cigar factory at Kornauer Straße 35.

The company was the first metalworking factory in the area, manufacturing and repairing electric motors and electric blowers. These were mainly used for bunker ventilation during the war.

In October 1942, the owner Karl W. Müller bought the patent for the LS 37 air-raid siren from Dr. Ing. W. Setzepfand from Berlin, who was also plant manager in Kirrlach from this point onwards.

Elektror was called “Siren Müller” in both Esslingen and Kirrlach.

The employees responsible for the 1st hour

Dr. Ing. W. Setzepfand – Plant manager (1942-1945)

Ing. Völlnagel – Deputy Chairman Plant management (until 1944)

Albert Zabler – Elektro Wickelmeister (from 1943)

Edelbert Müller – Master craftsman, turning shop (1942-1956)

Albert Day Master turner (1943-1944)

Karl Merz – Technical Director (1944-1945)

Ing. Wilhelm Fleck – Technical Director (1945-1946)

Rudi Pommer – Plant management (1945-1964)

Mr. Haussmann – Technical Manager (1946-1948)

Karl Merz – Technical Director (1948-1969)

First apprentice

Albrecht Heiler,

from November 2, 1942 as a technical draftsman. In December 1945, re-registered as a toolmaker.

Despite all the challenges, hardships and worries of the war years, Karl W. Müller also experienced some good things. He finds the love of his life in Margarete Bull. She was working at Elektror at the time, and their close collaboration led to trust and affection. Karl and Margarete walk down the aisle in 1945.

In 1945, Elektror used its motor expertise for reconstruction by repairing a wide variety of motors from rubble and scrap. Nevertheless, Karl W. Müller decides not to abandon his chosen path and to continue concentrating on the production of electrically driven fans.

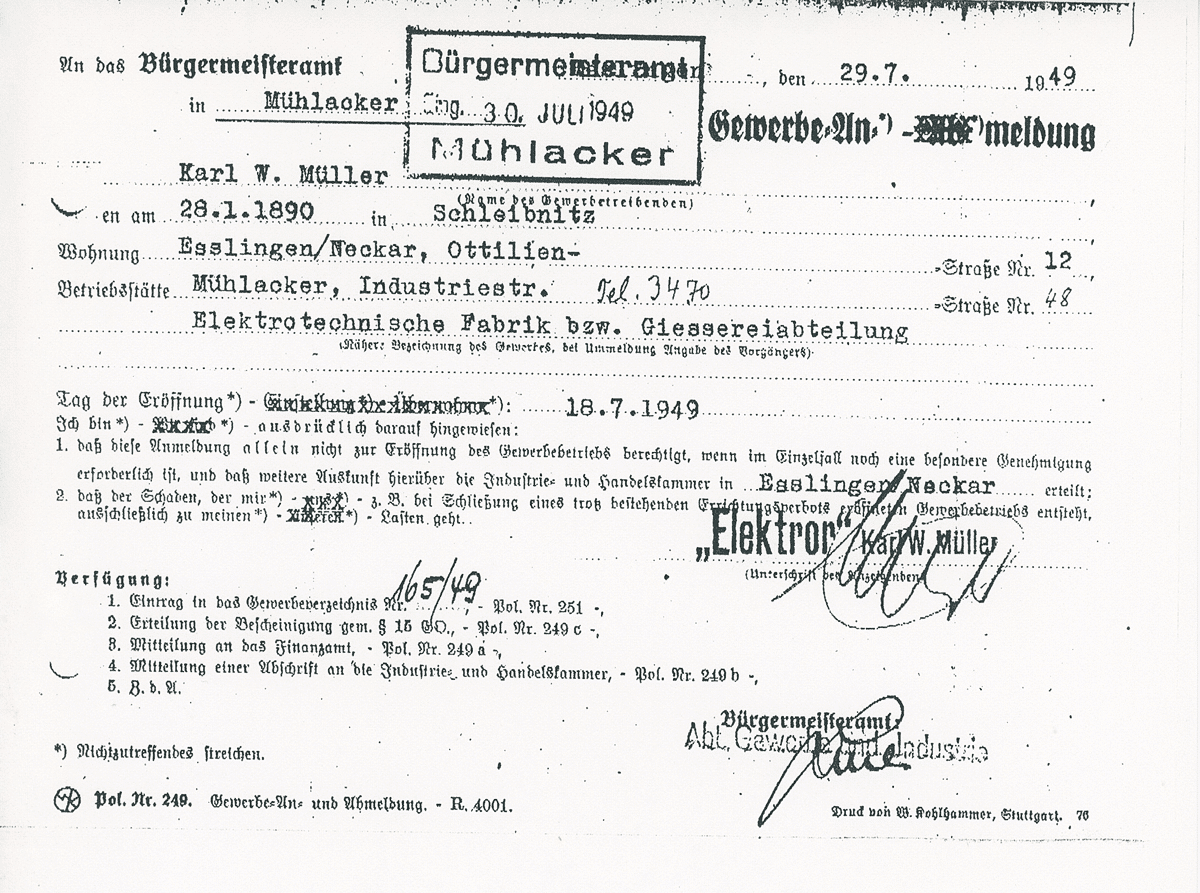

For this reason, an existing aluminum sand foundry in Mühlacker is taken over in 1948. This makes Elektror less dependent on the still difficult procurement of materials and lays the foundation for the further expansion of the product portfolio. Karl W. Müller exploited this decisive competitive advantage in 1949 and developed the world’s first series of centrifugal blowers made of cast aluminum. This development defined the company’s future core competence: the triad of motor, housing and impeller.